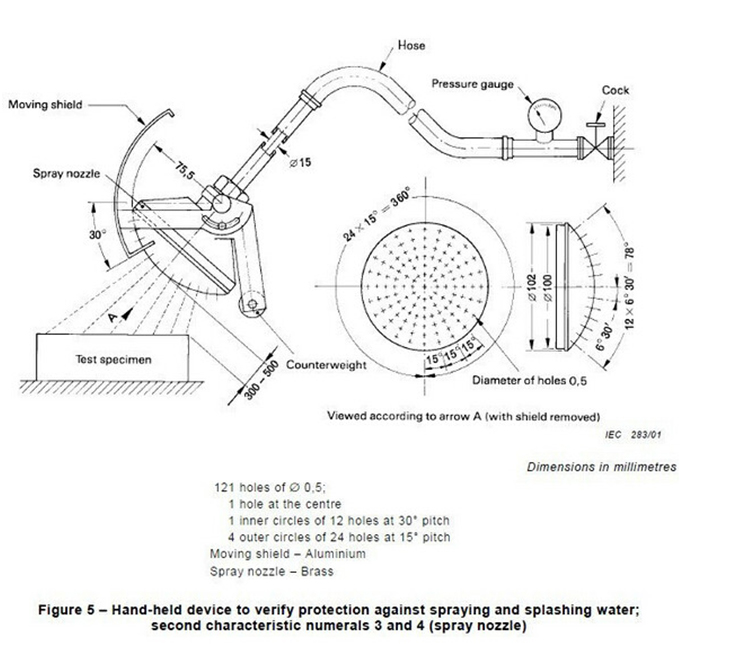

Technical Specifications

| Model |

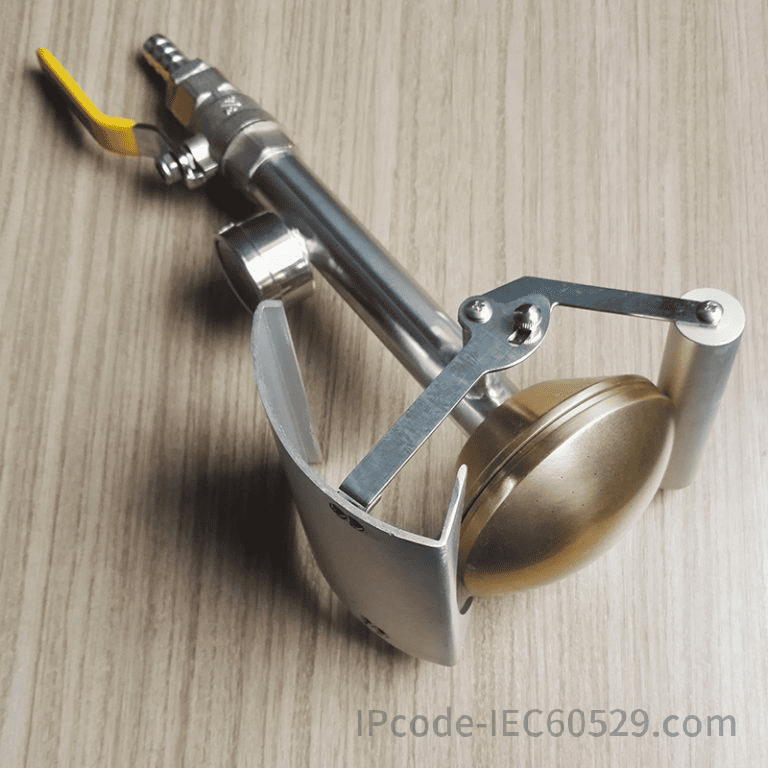

SHC-IPX34-SN |

| Water supply |

Water flow rate>10L/min±5% clean water without inclusion. |

| Control and operation |

valve, hand held |

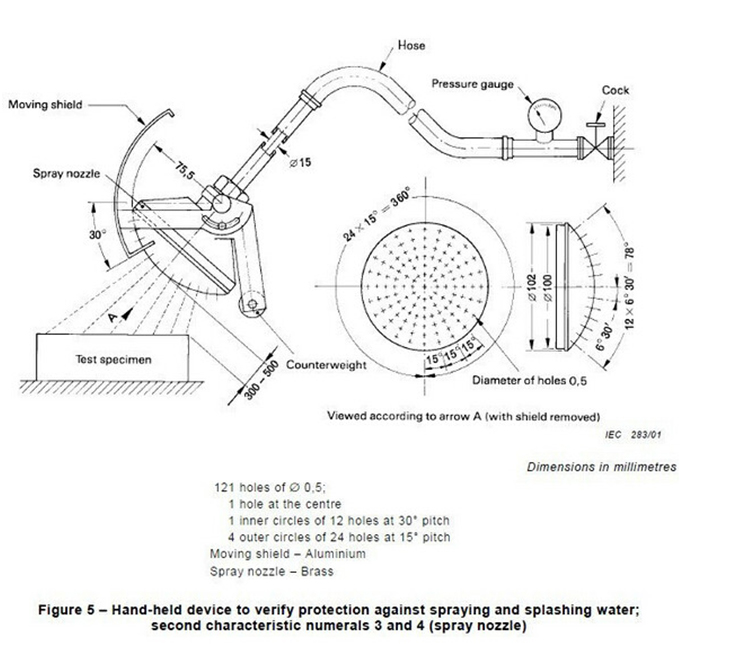

| Nozzle external diameter |

Ф102mm |

| Nozzle spherical diameter |

SФ75.5mm |

| Nozzle holes |

121 holes of Ф0.5mm

1 hole at the centre

1 inner circles of 12 holes at 30° pitch

4 outer circles of 24 holes at 15° pitch |

| Nozzle material |

Brass |

| Moving shield material |

Aluminum |

| Water flow |

10L/min±5%, Flow meter is adjustable |

| Pressure gauge |

50~150Kpa, Range of pressure gauge 0~0.25Mpa |

| Baffle |

Removable |

| Site requirements |

Dedicated IP waterproof test room,

The ground should be flat with illumination

With good function of inflow and drainage. |

| Testing time |

Manual control, at least 5min |

Product Description

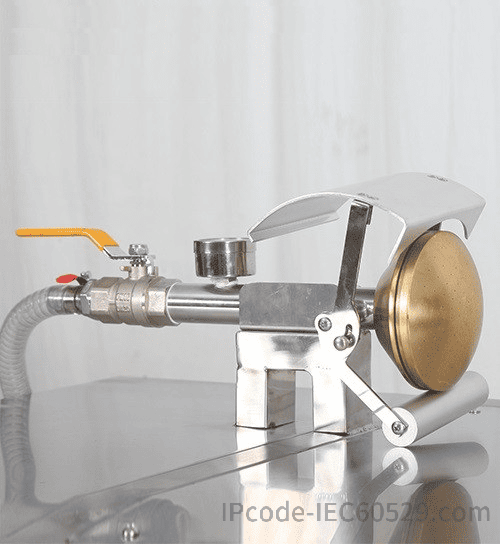

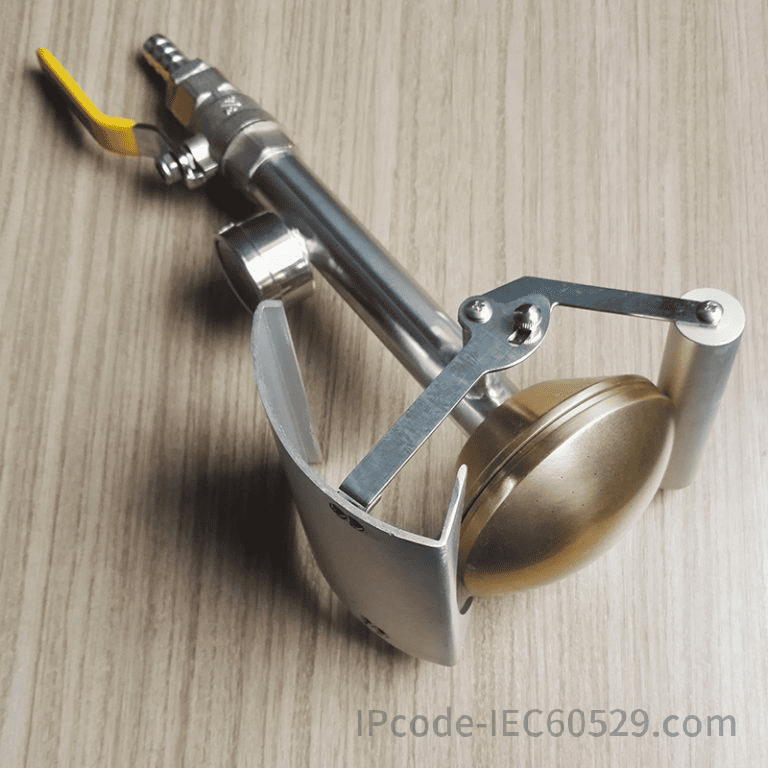

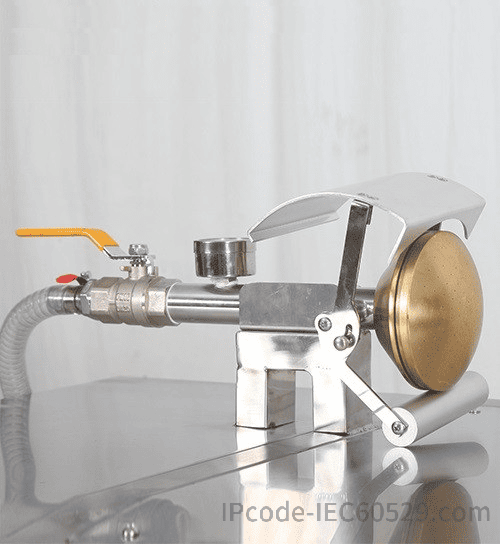

The IPX3/IPX4 spray nozzle hand-held device is designed for testing protection against spraying and splashing water. This versatile device can be used for both IPX3 (spraying water) and IPX4 (splashing water) tests according to IEC 60529 standard.

The device features a precisely machined spray nozzle that delivers the exact water flow rate and spray pattern required by the standard. The ergonomic handle design allows for comfortable operation during extended testing periods.

Compliance with Standards: The IPX3/4 spray nozzle is designed to comply with the specific requirements outlined in the IEC 60529 standard for ingress protection testing. Compliance ensures that the testing is conducted according to standardized procedures, providing reliable and comparable results.

During the IPX3/4 testing, the spray nozzle is positioned at a specified distance from the equipment being tested. The water is then sprayed onto the equipment from the defined angles and durations, simulating real-world conditions such as rain showers or splashing water. The test evaluates the equipment's ability to withstand the ingress of water and maintain its protection against water-related hazards.

It's important to note that the IPX3/4 spray nozzle is just one component of the overall testing setup for IPX3 and IPX4 testing. Other equipment, such as a test chamber or enclosure, may be used in conjunction with the spray nozzle to create the necessary testing environment and accurately assess the equipment's water resistance.

Structure:

This device is manufactured according IEC 60529 figure 5, it can achieve IPX3 / IPX4 hand-held spraying test by connecting water pipe.

It eEnsure that the water spraying and splashing speed reaches the standard required value by controlling the water supply flow, make the enclosure of the specimen to be splashed in all directions.

Normally we suggest to adopt the automatic control for IPX3/4 testing, if client has limit budget, the following easy installation for IPX3 and IPX4 testing is for reference:

Applications

- IPX3 spraying water protection testing

- IPX4 splashing water protection testing

- Product development and verification

- Quality control testing

- Certification testing for water protection

Package Includes

- 1 × IPX3/IPX4 Spray Nozzle Hand-held Device

- 1 × Pressure Gauge

- 1 × Water Quick Connect Adapter

- 1 × Calibration Certificate(Optional)

- 1 × User Manual